Packaging Machines for Southern Africa

Main menu:

Fipal

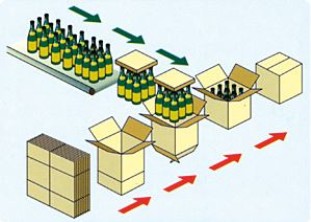

Inpakt group supplies cartoning machines, deppalletizer machines, carton forming machines, box erecting machines, carton divider inserting machines, carton closing machines,, palletising machines, case erector machines, case packer, case divider placing, case divider inserts, carton case sealer, box sealers, case palletising machines and case dividers, handle applying machine.

MINI DEPAL depalletizer

Bottle depalletising machine (with enflating tubes and pal remover)

DESCRIPTION

Designed to depalletise bottles with different diameter on 1200 mm x 800 mm or 1200x1000 pallets , maximum height 1800 mm.

The product feeding is at a low level and the head loading system is on still pallet.

It is equipped with a double column system on the vertical working axis and with a layer shifting cart on the horizontal axis.

It consists of:

BASIC FRAME

DEPALLETISING HEAD

PAINTED STEEL ELECTRIC BOARD

OPERATION

The structure is in embossed plate while the bearing and lifting pillar is in thick drawn bars.

The grip of the layer is through enflating tubes.

A vertical movement conveys and drops the layer on a moving platform; the containers are conveyed toward the ejector. The operations are powered by an operator through a control board on the side of the machine.

Depalletizer MINI DEPAL

Bottle depalletising machine (with enflating tubes and pal remover)

DESCRIPTION

Designed to depalletise bottles with different diameter on 1200 mm x 800 mm or 1200x1000 pallets , maximum height 1800 mm.

The product feeding is at a low level and the head loading system is on still pallet.

It is equipped with a double column system on the vertical working axis and with a layer shifting cart on the horizontal axis.

It consists of:

BASIC FRAME

DEPALLETISING HEAD

PAINTED STEEL ELECTRIC BOARD

OPERATION

The structure is in embossed plate while the bearing and lifting pillar is in thick drawn bars.

The grip of the layer is through enflating tubes.

A vertical movement conveys and drops the layer on a moving platform; the containers are conveyed toward the ejector. The operations are powered by an operator through a control board on the side of the machine.

D200-B depalletizer

Bottle depalletising machine

DESCRIPTION

Designed to depalletise bottles having varying diameters and heights on 1200 x 800 mm pallets, or 1200 x 1000 mm pallets with maximum height 2100 mm.

The product feeding is at a low level and the head loading system is on still pallet. It is equipped with a double column system on the vertical working axis and with a layer shifting. Interlayer device and different pallet conveyor belt can de added like optional.

Main components:

BASIC FRAME

DEPALLETISING HEAD

PAINTED STEEL ELECTRIC BOARD

OPERATION

The bottles that have been packed onto the pallet in layers with an interlayer are lifted by a vertical cart via a push-system, then driven to an intermediate position and transferred to a motorised table.

An automatic device will remove the interlayer above the layer of bottles just depalletised (if inserted as an accessory).

The cycle restarts with the head positioned on a new layer that is to be depalletised

MINI COMBI

COMBI packaging monobloc

Compact packaging combo unit with glue or tape seal

CARTON FORMING MACHINE - CARTONING MACHINE + divider inserting machine and carton sealing machine

COMPACT, MODULAR DESIGN

The basic machine is a very compact carton forming/ cartoning machine to which divider inserting and glue or tape seal carton closing units may be added.

EASY MANAGEMENT AND SIZE CHANGE

The machine is easy to run and size change is performed in a few steps without the use of wrenches.

RIABILITY - DURABILITY - PRECISION

The machine operates on a mechanical basis ensuring easy-of-running and high-level reliability, precision and working life.

Main structure in powder painted steel (Optional: stainless steel).

Pick-up head in continuous movement and easy-to-replace for size change.

Transparent Plexiglas safety guards with safety microswitches on the doors.

All funtions PLC-assisted with safety devices for each movement.

PACK 900/1500 carton forming machine

Case erector

DESCRIPTION

This fully automatic machine has been designed to seal bottom pads of American-type carton cases by glue hot-melt or tape PVC.

It consists in:

BASIC STRUCTURE

TROLLEY FOR GRIPPING AND FORMING BOXES

FLAP CLOSURE UNIT

GLUING UNIT

PRESSING UNIT

STEEL PAINTED CONTROL PANEL

OPERATION

The sucker arm picks the boxes from the magazine and drops them, closing its side flaps first, and after having pushed in the pressing unit, its upper and lower flaps.

The case sealing is executed through hot melt glue which ensures a safe fixing in accordance to the EEC standards.

The handwheel counter indicate the reference position for the various formats the machine can operate, this way making it easier and quck to select the format. The machine operations are supported by a PLC.

PACK 2100/2400 carton forming machine

Case erector

DESCRIPTION

This fully automatic machine has been designed to seal bottom pads of American-type carton cases by glue hot-melt or tape PVC.

It consists in:

BASIC STRUCTURE

TROLLEY FOR GRIPPING AND FORMING BOXES

FLAP CLOSURE UNIT

GLUING UNIT

PRESSING UNIT

PAINTED & STEEL CONTROL PANEL

OPERATION

The sucker arm picks the boxes from the magazine and drops them, closing its side flaps first, and after having pushed in the pressing unit, its upper and lower flaps.

The case sealing is executed through hot melt glue which ensures a safe fixing in accordance to the EEC standards.

The handwheel counter indicate the reference position for the various formats the machine can operate, this way making it easier and quck to select the format. The machine operations are supported by a PLC.

MINI BOXING 500/1000 cartoning machine

Case packer

DESCRIPTION

The above mentioned machine is completely automatic and suitable for packing glass and plastic bottles, jars, etc. in carton boxes, trays, PVC cases, with or without partitions.

It consists in:

BASIC FRAME

GRIPPING HEAD

BOX CONVEYOR

PRODUCTS TO BE PACKAGED CONVEYOR

MOBILE CENTERING DEVICE

PAINTED STEEL ELECTRIC BOARD

OPERATION

The container is stopped inside the conveyor by a mechanical stop, and a centering device ensures its correct positioning. Successively, the picking head picks up the product and places it on the containers bottom. All the machine functions are controlled by PLC, with safety devices on each movement

BOXING 1000/1500/2000/2500/3000 cartoning machine

Case packer

DESCRIPTION

The above mentioned machine is completely automatic and suitable for packing glass and plastic bottles, jars, etc. in carton boxes, trays, PVC cases, with or without partitions.

It consists in:

BASIC FRAME

GRIPPING HEAD

BOX CONVEYOR

PRODUCTS TO BE PACKAGED CONVEYOR

MOBILE CENTERING DEVICE

PAINTED STEEL ELECTRIC BOARD

OPERATION

The container is stopped inside the conveyor by a mechanical stop, and a centering device ensures its correct positioning. Successively, the picking head picks up the product and places it on the containers bottom. All the machine functions are controlled by PLC, with safety devices on each movement containers bottom. All the machine functions are controlled by PLC, with safety devices on each movement

MINI PAL palletising machine

Case palletising machine

DESCRIPTION

Designed to palletise packs (boxes, cases, bundles) on 1200 mm x 800 mm pallets (Europallets), maximum height 2100 mm.

The product feeding is at a low level and the head loading system is on still pallet.

It is equipped with a double column system on the vertical working axis and with a layer shifting cart on the horizontal axis.

It consists of:

BASIC FRAME

PALLETISING HEAD

PAINTED STEEL ELECTRIC BOARD

OPERATION

The product comes from the pacing conveyor where the row that will form the layer is programmed. Aflerwards, a push-off moves the rows onto a fixed plane and then onto a mobile plane supported by the lifting head. The latter moves up to the last layer of the pallet, translates the mobile plane containing the product layer and deposits it on the pallet, which comes from the pallet magazine due to a motordriven roller.

INSER 1200 divider inserting machines

Case divider placing

DESCRIPTION

Fully automatic machine designed to place the dividers inside carton cases. The dividers can be placed either before or after the product (bottles, cans etc.) has been put into the cases, in this case after having in-serted bottles. Dividers must be 0,7 mm

A major feature of this unit is a quick, easy changeover to eliminate costly machine downtime.

The machine consist of:

BASIC FRAME

GRIPPING HEAD

BOX CONVEYOR BELT

DIVIDER CONVEYOR

PAINTED STEEL ELECTRICAL BOARD INCLUDING

OPERATION

The head of the machine picks the divider and, during its path towards the case, spreads it open and places it onto the case. The operation is controlled by a PLC with safety devices distributed on the unit where re-quired

INSER 1200 divider inserting machines

Case divider placing

DESCRIPTION

Fully automatic machine designed to place the dividers inside carton cases. The dividers can be placed either before or after the product (bottles, cans etc.) has been put into the cases, in this case after having in-serted bottles. Dividers must be 0,7 mm

A major feature of this unit is a quick, easy changeover to eliminate costly machine downtime.

The machine consist of:

BASIC FRAME

GRIPPING HEAD

BOX CONVEYOR BELT

DIVIDER CONVEYOR

PAINTED STEEL ELECTRICAL BOARD INCLUDING

OPERATION

The head of the machine picks the divider and, during its path towards the case, spreads it open and places it onto the case. The operation is controlled by a PLC with safety devices distributed on the unit where re-quired

LOCK 900/1500 carton closing machines

Carton case sealer

DESCRIPTION

This fully automatic machine has been designed to seal carton cases with gluing or tape PVC sealing unit.

It consists of:

BASIC STRUCTURE

SIDE BELTS

GLUING UNIT

UPPER FLAP CLOSURE UNIT

PRESSING UNIT

CONTROL PANEL IN VARNISHED STEEL

OPERATION

The side belts on the entrance phases pick up the box to transport it with the main conveyor to the gluing unit. As the box advances the front flap is closed, while the rear flap is closed by the pneumatic lever device; subsequently the side flaps are closed by the steel rods. The case sealing is executed by hot-melt glue spraying, which ensures a safe fixing of the case flaps in accordance with the EEC standards.

All adjustments relative to size change are facilitated by the presence of flywheels or cranks that indicate the reference position of the different sizes that the machine can produce; all with the maximum rapidity.

LOCK 1800/2100/2400/3600 carton closing machines

Carton case sealer

DESCRIPTION

This fully automatic machine has been designed to seal top pads of American-type carton cases by glue hot-melt or tape PVC.

It consists in:

BASIC STRUCTURE

SIDE BELTS

GLUING UNIT

UPPER FLAP CLOSURE UNIT

PRESSING UNIT

PAINTED & STEEL CONTROL PANEL

OPERATION

The side belts on the entrance phases pick up the box to transport it with the main conveyor to the gluing unit. As the box advances the front flap is closed, while the rear flap is closed by the pneumatic lever device; subsequently the side flaps are closed by the steel rods. The case sealing is executed by hot-melt glue spraying, which ensures a safe fixing of the case flaps in accordance with the EEC standards.

All adjustments relative to size change are facilitated by the presence of flywheels or cranks that indicate the reference position of the different sizes that the machine can produce; all with the maximum rapidipneumatic lever device; subsequently the side flaps are closed by the steel rods. The case sealing is executed by hot-melt glue spraying, which ensures a safe fixing of the case flaps in accordance with the EEC standards.

All adjustments relative to size change are facilitated by the presence of flywheels or cranks that indicate the reference position of the different sizes that the machine can produce; all with the maximum rapidity.

DESCRIPTION

Designed to palletise packs (boxes, cases, bundles) on 1200 mm x 800 mm pallets (Europallets), maximum height 2100 mm.

The product feeding is at a low level and the head loading system is on still pallet.

It is equipped with a double column system on the vertical working axis and with a layer shifting cart on the horizontal axis.

It consists of:

BASIC FRAME

PALLETISING HEAD

PAINTED STEEL ELECTRIC BOARD

OPERATION

The product comes from the pacing conveyor where the row that will form the layer is programmed. Aflerwards, a push-off moves the rows onto a fixed plane and then onto a mobile plane supported by the lifting head. The latter moves up to the last layer of the pallet, translates the mobile plane containing the product layer and deposits it on the pallet, which comes from the pallet magazine due to a motordriven roller.

PAL 20 palletising machine

Case palletising machine

DESCRIPTION

Designed to palletise packs (boxes, cases, bundles) on 1200 mm x 800 mm pallets (Europallets), maximum height 2100 mm.

The product feeding is at a low level and the head loading system is on still pallet.

It is equipped with a double column system on the vertical working axis and with a layer shifting cart on the horizontal axis.

It consists of:

BASIC FRAME

PALLETISING HEAD

PAINTED STEEL ELECTRIC BOARD

OPERATION

The product comes from the pacing conveyor where the row that will form the layer is programmed. Aflerwards, a push-off moves the rows onto a fixed plane and then onto a mobile plane supported by the lifting head. The latter moves up to the last layer of the pallet, translates the mobile plane containing the product layer and deposits it on the pallet, which comes from the pallet magazine due to a motordriven roller.

PAL 30/40/80/100 palletising machine

Case palletising machine

DESCRIPTION

Designed to palletise packs (boxes, cases, bundles) on 1200 mm x 800 mm pallets (Europallets), maximum height 2100 mm.

The product feeding is at a low level and the head loading system is on still pallet.

It is equipped with a double column system on the vertical working axis and with a layer shifting cart on the horizontal axis.

It consists of:

BASIC FRAME

PALLETISING HEAD

PAINTED STEEL ELECTRIC BOARD

OPERATION

The product comes from the pacing conveyor where the row that will form the layer is programmed. Aflerwards, a push-off moves the rows onto a fixed plane and then onto a mobile plane supported by the lifting head. The latter moves up to the last layer of the pallet, translates the mobile plane containing the product layer and deposits it on the pallet, which comes from the pallet magazine due to a motordriven rolle